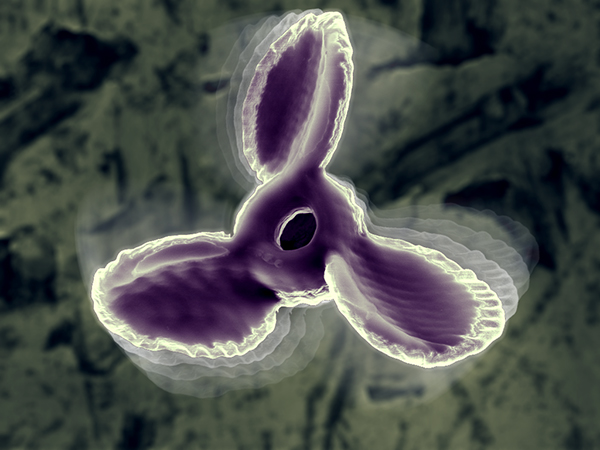

Additive manufacturing, also known as 3-D printing, refers to a process in which objects are produced layer by layer from a digital file or model. The technology has the potential to find new applications for virtually every material, as well as the potential to create new alloys and composites not previously possible. The uses for this technology and the materials it will employ have the potential to revolutionize nearly every aspect of life and is already in use in the areas of architecture, medicine, art, fashion, consumer goods, electronics, and specialty manufacturing of all kinds.