Most recently, Beese was awarded the Faculty Scholar Medal in Engineering, one of Penn State’s highest honors for scholarly achievement, recognizing her transformative contributions to the understanding of AM metals over the past five years. She also received the Wilson Award for Excellence in Research, one of the highest research honors bestowed by the College of Earth and Mineral Sciences.

“I’m deeply honored for this recognition and am especially grateful for my wonderful group of graduate and undergraduate students, collaborators, and those that nominated me for these awards” Beese said.

Beese’s research has revealed the complex relationships between process, structure, and properties (PSP) in alloys produced through AM. Although additive manufacturing is already reshaping modern industrial production, it presents ongoing challenges—among them, the variability in material properties caused by complex interactions between energy sources and feedstock materials, which can introduce defects during printing.

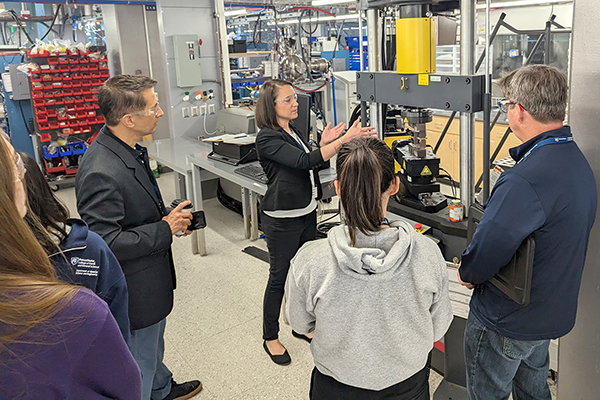

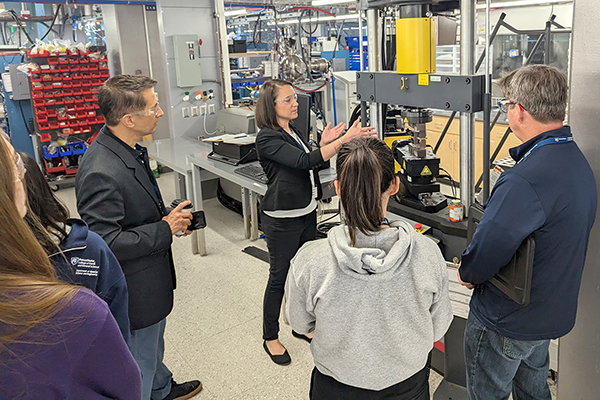

At the forefront of tackling these challenges, Beese has developed unique experimental capabilities that enable her team to study materials processed under a range of conditions and subjected to a wide range of loading conditions. By combining advanced experimental setups with deep material insights, the Beese research group has provided a more complete understanding of how internal defects, like pores, influence failure mechanisms in AM and traditionally processed metals.

“Our research aims to enable the safe adoption of AM for structural applications by bringing an understanding of the impacts of natural stochastic defects during processing on resultant component properties and through harnessing of in process signals to predict and certify properties.”

In addition to her work on defect behavior, Beese is a pioneer in developing functionally graded metals (FGMs)—components that leverage chemical and mechanical gradients to tailor spatial functionality. Using directed energy deposition (DED), her team has successfully fabricated parts that transition between dissimilar alloys, eliminating the need for abrupt welds, joints, or coatings. This innovation not only improves structural efficiency but also expands the design possibilities for applications ranging from aerospace to biomedical devices.

A hallmark of Beese’s approach is her deeply interdisciplinary methodology. Her work blends mechanics, materials science, data analytics, computational modeling, and characterization, giving her a unique edge in solving complex problems. What distinguishes Beese is her comprehensive expertise across all critical facets of metal additive manufacturing—from computational modeling to hands-on processing and characterization. She seamlessly integrates principles from physics, computer science, and materials science to tackle AM’s most complex, multi-layered challenges.

A hallmark of Beese’s approach is her deeply interdisciplinary methodology. Her work blends mechanics, materials science, data analytics, computational modeling, and characterization, giving her a unique edge in solving complex problems. What distinguishes Beese is her comprehensive expertise across all critical facets of metal additive manufacturing—from computational modeling to hands-on processing and characterization. She seamlessly integrates principles from physics, computer science, and materials science to tackle AM’s most complex, multi-layered challenges.

Equally important is Beese’s ability to lead large, collaborative research efforts. She has assembled and led interdisciplinary teams that include partners from industry, national labs, and universities, earning a reputation as the visionary “glue” that unites experts around high-impact research goals.

Over the past five years, Beese’s work has led to fundamental insights into how microstructures and defects govern multiaxial deformation and failure in AM metals. Her innovations in FGMs have opened new pathways for material design and process optimization. Her hybrid experimental-computational methods have produced feasibility diagrams now used globally to qualify AM parts for safe deployment in structural components, customized medical implants, and lightweight applications that address critical supply chain and design challenges.

Internationally respected for her leadership, Beese seamlessly merges cutting-edge techniques like machine learning and computer vision with traditional materials science approaches, helping bridge the gap between processing parameters, microstructure evolution, and mechanical performance. Her team is paving the way for safe AM adoption in structural components and has made seminal contributions to one of the most urgent challenges in the field.

As a groundbreaking researcher, visionary leader, and dedicated educator, Allison Beese stands out as a highly celebrated faculty member in MatSE. She holds multiple roles at Penn State, serving as a professor of materials science and engineering and of mechanical engineering, director of the Additive Manufacturing and Design Graduate Program, co-director of the Center for Innovative Materials Processing through Direct Digital Deposition, and the department’s associate head for diversity, equity, enclusion, and belonging. Internationally recognized for her expertise in mechanics and the additive manufacturing (AM) of alloys, Beese is helping to define the future of materials science.

As a groundbreaking researcher, visionary leader, and dedicated educator, Allison Beese stands out as a highly celebrated faculty member in MatSE. She holds multiple roles at Penn State, serving as a professor of materials science and engineering and of mechanical engineering, director of the Additive Manufacturing and Design Graduate Program, co-director of the Center for Innovative Materials Processing through Direct Digital Deposition, and the department’s associate head for diversity, equity, enclusion, and belonging. Internationally recognized for her expertise in mechanics and the additive manufacturing (AM) of alloys, Beese is helping to define the future of materials science.

A hallmark of Beese’s approach is her deeply interdisciplinary methodology. Her work blends mechanics, materials science, data analytics, computational modeling, and characterization, giving her a unique edge in solving complex problems. What distinguishes Beese is her comprehensive expertise across all critical facets of metal additive manufacturing—from computational modeling to hands-on processing and characterization. She seamlessly integrates principles from physics, computer science, and materials science to tackle AM’s most complex, multi-layered challenges.

A hallmark of Beese’s approach is her deeply interdisciplinary methodology. Her work blends mechanics, materials science, data analytics, computational modeling, and characterization, giving her a unique edge in solving complex problems. What distinguishes Beese is her comprehensive expertise across all critical facets of metal additive manufacturing—from computational modeling to hands-on processing and characterization. She seamlessly integrates principles from physics, computer science, and materials science to tackle AM’s most complex, multi-layered challenges.