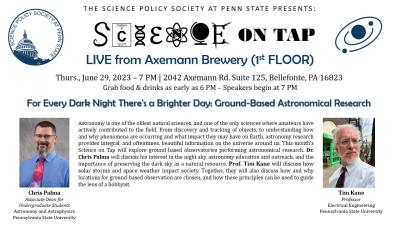

Date

June 29, 2023

Time

7:00 pm

Location

First floor of Axemann Brewery in Bellefonte

Description

Our speakers will discuss their work in ground-based astronomical research, how space weather impacts society, and astronomy outreach and education. This event will be Thursday, June 29th on the first floor of Axemann Brewery in Bellefonte. Talks will start at 7 PM, but attendees may arrive as early as 6 PM to grab a drink, food, and seat. Hope to see you there!

Speakers:

Chris Palma, Associate Dean for Undergraduate Students of Astronomy and Astrophysics at Penn State

Tim Kane, Professor of Electrical Engineering at Penn State

Cost

Free